Technology and processing possibilities

Industrial customers value HECKER®’s uncompromising service portfolio: the one-of-a-kind combination of hands-on expertise (“craft”) of its skilled workers gathered over decades, its high precision CNC machinery and use of first-class plastic brand-name semi-finished products, such as PLEXIGLAS® and EXOLON® GP made of MAKROLON®. You only need four minutes to get your first live impression of HECKER® plastic technology and manufacturing.

Brief overview of HECKER® production possibilities

Extensive machinery for milling, lathing, diamond polishing

Technological level: 5-axis simultaneous CNC milling up to 3050 x 2050 x 700 mm

Cold bending in XL format

EXOLON® GP made of MAKROLON® – warp-free cold bending up to 12 mm thickness and 3050 mm length

Brilliant PLEXIGLAS® + EXOLON® GP made of MAKROLON® – bonding and joining technologies

Fascinating range of recipes. Example: EXOLON® GP made of MAKROLON® – outstanding optical bonding.

Thermal forming

Thermal forming furnaces up to 3100 X 2100 X 2100 mm

Machinery for thermal forming up to a length of 3050 mm

PLEXIGLAS® VERWALZTECHNIK® (patented surface adhesion solution)

Heated PLEXIGLAS® surfaces are laminated together with the inserted object without any adhesive, that is, they are permanently rolled together applying pressure to form a a single brilliant transparent PLEXIGLAS® body.

The object appears to be suspended in the middle of the acrylic glass material.

Quality semi-finished goods for fast, precision production start:

PLEXIGLAS® + EXOLON® GP made of MAKROLON® large high bay warehouse with over 200 pallet bays and high-performance dividing saws

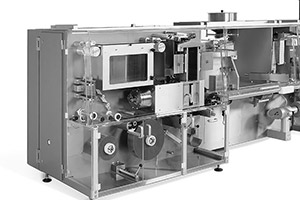

Protective Shielding for Machinery

Protective Shielding for Machinery Medical & Lab Technology

Medical & Lab Technology Functional and Simulation Models

Functional and Simulation Models Special Tubes and Hoppers

Special Tubes and Hoppers Plastics Technology

Plastics Technology Surface Finishing

Surface Finishing