printing · coating · foiling

has become increasingly important in the field of plastics technology in the last years.

You can choose from a wide range of methods and procedures for finishing transparent plastic semi-finished goods made of PLEXIGLAS® / acrylic glass and others: from abrasion-resistant, so-called “scratch-resistant” surfaces to anti-static coatings up to and including finishing with screen-printing or a transparent printed film.

As an attractive alternative to glass, PLEXIGLAS® / acrylic glass has already established itself on the market and continues to grow in popularity thanks to its appearance not to mention weight reducing properties. The material PLEXIGLAS® / acrylic glass is also a brilliant solution both as a printed display for medical devices as well as for room control units.

Anti-static, transparent ESD panes

HECKER® meets the stringent requirements of ESD applications through the use of semi-finished products with the very best technical quality and antistatic coating of

- PVC glass, transparent

- Polycarbonate / EUROPLEX® EC or SDX-F

- PLEXIGLAS® / acrylic glass

from leading brand-name manufacturers (trademarks e.g. EXOLON® GP made of MAKROLON®, LEXAN®, PLEXIGLAS®).

Abrasion-resistant, transparent sheets

As a basis for making flat technical drawing-based parts with a high level of abrasion resistance, the following is available as a semi-finished primary material with a thickness of 3–12 mm x 3000 x 2000 mm:

Polycarbonate sheets, e.g. EXOLON® GP made of MAKROLON® AR® HARD sheets*) improved abrasion resistance compared to non-coated plastic.

Chemical-resistant, transparent sheets

As an alternative semi-finished primary material for making flat technical drawing-based parts that are highly resistant to chemicals the following is available:

- EXOLON® GP made of MAKROLON® AR® scratch-resistant on both sides,

3,000 x 2,000 mm with a thickness of 3– 12mm - PLEXIGLAS ® Optical HC scratch-resistant on one side,

3,050 x 2,050 mm with a thickness of 2–8 mm

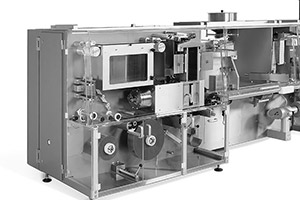

Protective Shielding for Machinery

Protective Shielding for Machinery Medical & Lab Technology

Medical & Lab Technology Functional and Simulation Models

Functional and Simulation Models Special Tubes and Hoppers

Special Tubes and Hoppers Plastics Technology

Plastics Technology Surface Finishing

Surface Finishing